DIT Kevin Shiramizu talks about his life on-set, liaising between production and post, and how he uses AJA routing and conversion gear to share the DoP's creative vision with everyone on set

For Digital Imaging Technician (DIT) Kevin Shiramizu, video production is a microcosm of the real world. He is able to use his work not just as a medium for very close collaboration but also to share the human experience, a dream job that he says he feels very lucky to have. Here, he talks about his work, and describes how he using AJA routing and conversion gear on set and how his role is constantly evolving.

“I studied film at the University of Colorado, where I thought I’d spend my entire career in a dark room,” Kevin said. “I swore I’d never move to LA and work in showbiz. Yet, ten years later, here I am, and I don’t regret it. I started out as a production assistant, then became an assistant cameraman. I tried other departments but came back to the DIT role because it best fit my skill set. I get to combine a little bit of creativity with a lot of technical execution to help everyone get through the day, which I love.

Sharing the Vision

As the DIT’s main role is liaising between production and post, while on-set Kevin troubleshoots everything, from the image sensor through to the hard drives, as well as the signal path to process the image and distribute it to monitors around the set. “On commercials, I'm also managing the data, which involves loading duties and coordinating with post to make sure that they're getting what they need.

“I primarily collaborate with the director of photography (DoP). Everyone needs to be able to see the DoP’s vision accurately and consistently – whether they’re on the video tape recorder (VTR) monitors, iPads or monitors the director are using. To that end, I also support the camera department and work with the assistant cameraman, digital dailies and VTR operators.”

He feels that this role has become especially important in modern productions because, as the industry moves toward digital workflows, production has become infinitely complex. “It’s crucial to mitigate problems early,” he said. “The work the DIT does on set with the cinematographer to get the look of the project dialled in also helps speed things up in post, which is great for tight turnaround projects. Often, it can actually be much easier to fix issues on set than in post.”

The Never-ending Challenge

Kevin works primarily on commercials for sports and pharmaceutical companies as well as consumer goods, personal care and apparel brands, often through personal reference. His typical projects take about a day to complete, but a longer job might last five days or up to ten weeks. He said, “Taking on shorter jobs means I work with a diverse group of people and projects, solving for different challenges – it’s like trying to solve a never-ending Rubik's Cube. Learning to work with such an eclectic mix of personalities, gear and conditions has helped make me be better at what I do.

“Whether I’m working with a different camera, trying to achieve a set look for the actors, or the project suddenly needs to take on a certain style, I need to navigate a never-ending permutation of factors to make each shoot happen, which is challenging. There’s always something new to try to figure out or troubleshoot, and often, just as soon as I think I've got it, something changes and then I’ll have to figure that out.”

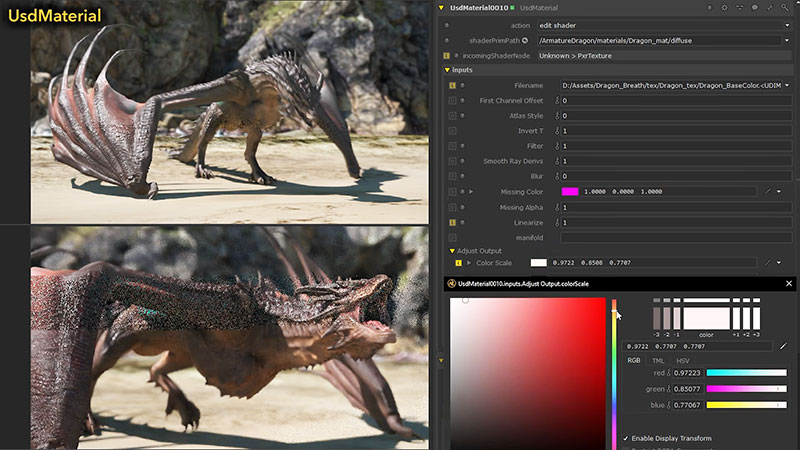

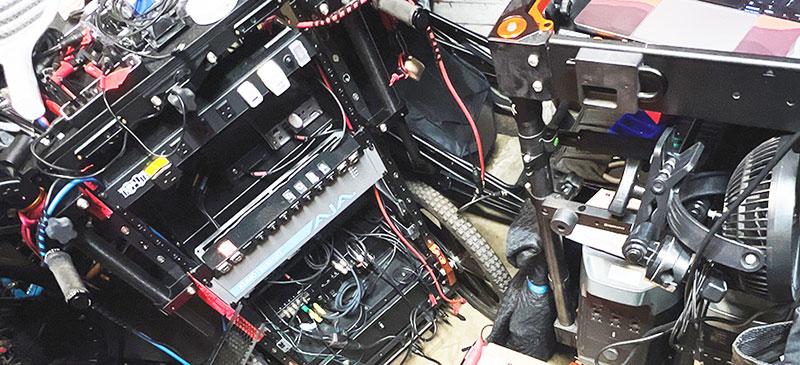

On the Cart

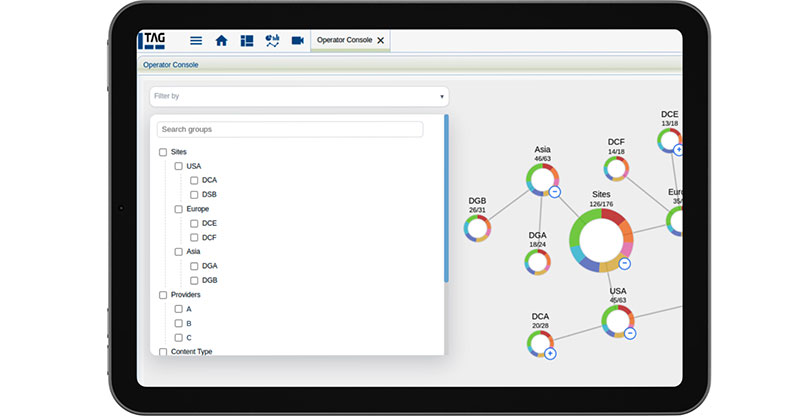

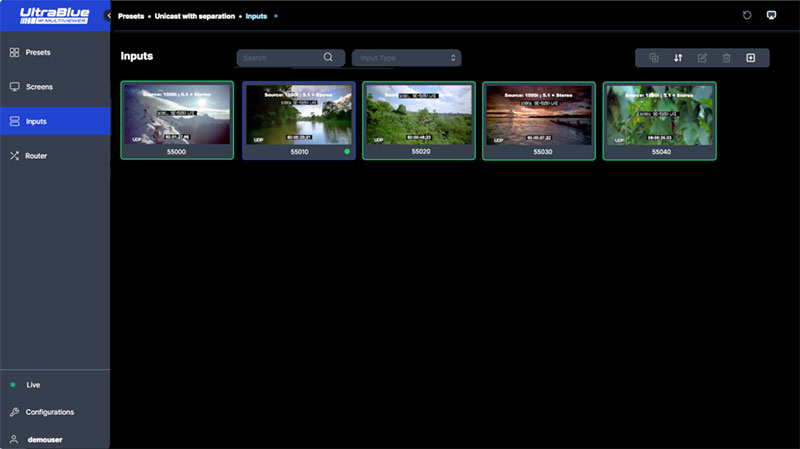

He works mainly from his DIT cart, but also has a mobile set-up in case he has to work on a location where a cart weighing hundreds of pounds is too cumbersome, like on a boat or rooftop. On the cart, a computer runs Pomfort’s Livegrade software, monitors and the video signal path from the camera, which may be wireless or tethered through cloud tools. The signal runs through LUT boxes into the computer, through his router, and is then distributed to his cart monitors, the DoP’s and director’s monitors, and the VTR, who can stream it to remote clients, the hair and makeup team, or anyone else who needs it.

“Generally, I receive signals through a wireless video system via SDI into my AJA KUMO 3232-12G router. I might use an AJA HDMI to SDI converter if the wireless receiver is HDMI, but most often, I’m coming in via SDI. For live grading, I use Livegrade and a Tangent panel. The fact that AJA and Pomfort support direct software integration is awesome, and with 32 I/O ports on the KUMO, I’m looking forward to moving to Livegrade Studio in the future.

Adding to the functionality of Livegrade Pro digital imaging software, Livegrade Studio is optimised for multi-camera setups, and comes with grading modes for the standard industry colour pipelines. It also allows users to precisely share looks and metadata across the various production and post teams.

Ins and Outs

Kevin remarked that KUMO makes planning ahead a little easier because he knows it will last ten years or more, especially in the context of DIT gear, where tools and processes change quickly. “Sometimes I’m lucky to get six months out of a piece of gear. I also keep AJA Mini-Converters on my cart to support conversion demands, whether HDMI to SDI or for distribution amplification [taking a single input and delivering this same signal to multiple isolated outputs].

“They also help manage curve balls on set – say, if I suddenly have to monitor an iPhone, a GoPro, Sony SLR cam or other capture device. Having a collection of AJA Mini-Converters in my toolkit for those moments has saved the day countless times. I’m also looking at integrating AJA ColorBox into my cart for colour space and HDR format conversions. As productions grow in complexity, more people on set want access to monitors to get through the day – having enough ins and outs is crucial to ensure that we all get to go home on time.”

Ahead of the Curve

KUMO lends redundancy and flexibility to a project. Kevin has worked with KUMO 1616 for some years, and now includes it in his mobile kit. AJA gear has been extremely reliable, and makes him feel prepared even as the industry shifts toward 4K HDR monitoring and 12G-SDI becomes more widely adopted on set. “I love being ahead of the curve,” he said. A recent example of how working with adaptable equipment has opened opportunities for Kevin is shooting against LED walls. He has enjoyed stepping into that environment and working with the technical stage managers to figure out how to eliminate flicker in an image, for instance, and synchronise everything.

“There’s something rewarding about using our collective intelligence to work around some of these challenges and make the image play right with the camera, whether determining the right gen lock on cameras to keep everything in sync, or making a shot look real so everyone on set can understand the vision,” Kevin said. “It’s both difficult and exciting to help people see what is or is not there on the LED wall and to guide them on decisions that can make the shot look more realistic, make it feel more natural for the actors, or give the director the image that they're looking for.”

On the Cards

Among future trends, Kevin is watching 4K HDR monitoring, which is already starting to happen on set, but which he believes will eventually become the standard, as monitoring and camera technologies become more capable. Remote live grading workflows will also continue to expand, and the process will be much smoother in the future.

Going back to virtual production and LED walls, he expects they will also become more common as the tools become more accessible. “I see them being used to replace process trailers [pulled behind a tracking vehicle carrying the camera crew], which make vehicle shots complicated and inherently dangerous to shoot,” he noted. “Having people on a stage in a built environment, where there's so much more control, also means that we're not causing huge traffic jams.

“It’s just a safer way of working and opens the option to shoot a project in a city during a chosen time period. Because it gives actors a frame of reference to work with, it can improve performances. The technology is still young, and will only get better.” www.aja.com