wTVision’s business focusses on helping clients take advantage of broadcast developments through their own products and services, incorporating AJA gear for reliability and consistency.

Expanding adoption of virtual set and IP workflows are generating rapid change across live production and broadcast pipelines, supported by new cloud, virtualisation and IP systems. Broadcast services provider wTVision makes it their business to keep up with all of these developments and help professionals take advantage of them through their own products and services.

Founded in Lisbon 2001, wTVision is part of audiovisual company GRUP MEDIAPRO, and now employs over 350 people at offices in Europe, North America, South America, the Middle East and Asia. It develops broadcast graphics, automation and playout, data and sports, augmented reality (AR), virtual studio and media asset management (MAM) equipment deployed by broadcasters, sports networks, entertainment channels and production companies in over 120 countries.

The company's team run more than 15,000 broadcasting operations each year, to support sports productions, election coverage, production control room (PCR) and master control room (MCR) operations, playout automation, broadcast design and post-production.

Hardware Support

The reliability and quality of their live video capture and playout are critical factors for wTVision. Many of their turnkey systems include a combination of AJA Corvid 88, Corvid 44 12G and/or KONA I/O cards. The team uses the AJA Developer SDK to build the technologies into custom systems. Its graphics servers, for instance, include AJA I/O cards to set up the output of synchronized key and fill signals up to UltraHD (2SI or SQD). According to Daniel Gonçalves, wTVision Innovation and Pre-Sales Director, the stability of each card means that they can deliver consistent, high-quality video at an affordable price.

Numbers of AJA Mini-Converters are also integrated into the team’s live production kits, which need to support diverse conversion, sync generation and distribution amplification operations. "The AJA Mini-Converters have the necessary reliability, even in adverse production scenarios," Daniel said.

Out in the field, AJA mobile Io hardware supports its operators as they output video and graphics over key and fill signals. "The rugged design, performance and portability of AJA's Io tools have made them our choice for production on location, and we include them in the list of recommended hardware we share with clients," said Daniel.

wTVision's Headquarters

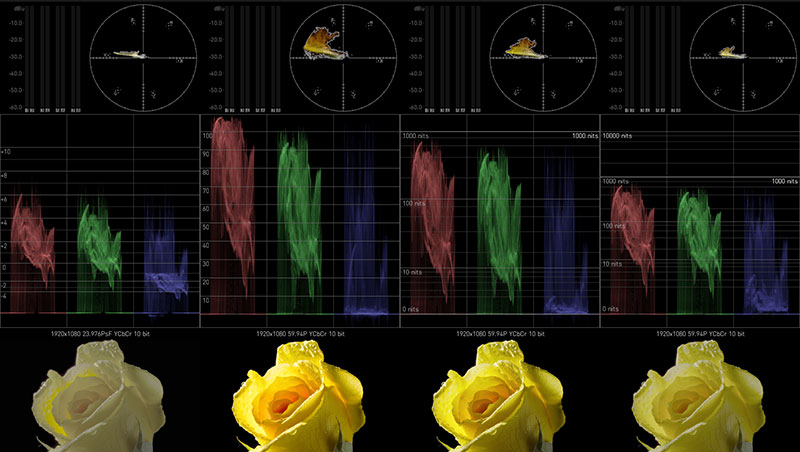

AJA gear is also integrated into wTVision's headquarters, which houses a data centre hosting multiple client TV channels, an MCR operations centre and a studio with a chroma key set where clients produce and record live shows. The infrastructure behind this set includes several AJA products, including openGear hardware and Ki Pro recorders. In this case, they also run an R&D Lab, which houses an AJA HDR Image Analyzer 12G HDR waveform, histogram, and vectorscope monitoring solution for HDR-related developments and certifications. Its broad feature set allows wTVision's R&D team to analyze and monitor HDR content precisely, ensuring compliance with industry standards.

More recently, wTVision's team has started using BRIDGE NDI 3G for HD and UltraHD remote productions. "In particular, BRIDGE NDI 3G is making our operations more efficient while helping to push our sustainability efforts ahead," Daniel said. "For instance, our 3D graphics engine R3 Space Engine can output NDI or NDI HX from cloud environments and deliver synchronised key and fill feeds directly from a venue. With the BRIDGE, we can reduce the volume of equipment and personnel travelling between venues. Not only more efficient, we have become more flexible and lowered our logistical costs."

Virtualisation and the Cloud

Looking ahead, wTVision wants to make further use of virtualisation for large production environments to simplify infrastructure, allocate resources more efficiently and save money. They also look forward to using cloud infrastructure more widely to reduce on-site equipment, travel and environmental stress while incresing flexibility. The team continually explores new remote workflows and architectures as well. A specific goal is to continue delivering ways automate tedious processes, which is where Daniel sees AJA’s devices playing an especially important role.

"AJA's engineering quality means that our kits remain durable and reliable, even in demanding environments, and that we can maintain consistent performance and limit downtime. The gear can withstand the physical stresses of frequent setup, teardown and transit between contrasting environments. The gear also complies widely with industry standards, making it simpler to integrate with other equipment in our systems and workflow. By reducing the time we spend on technical issues, we can focus more on developing competitive systems and content for clients." www.aja.com